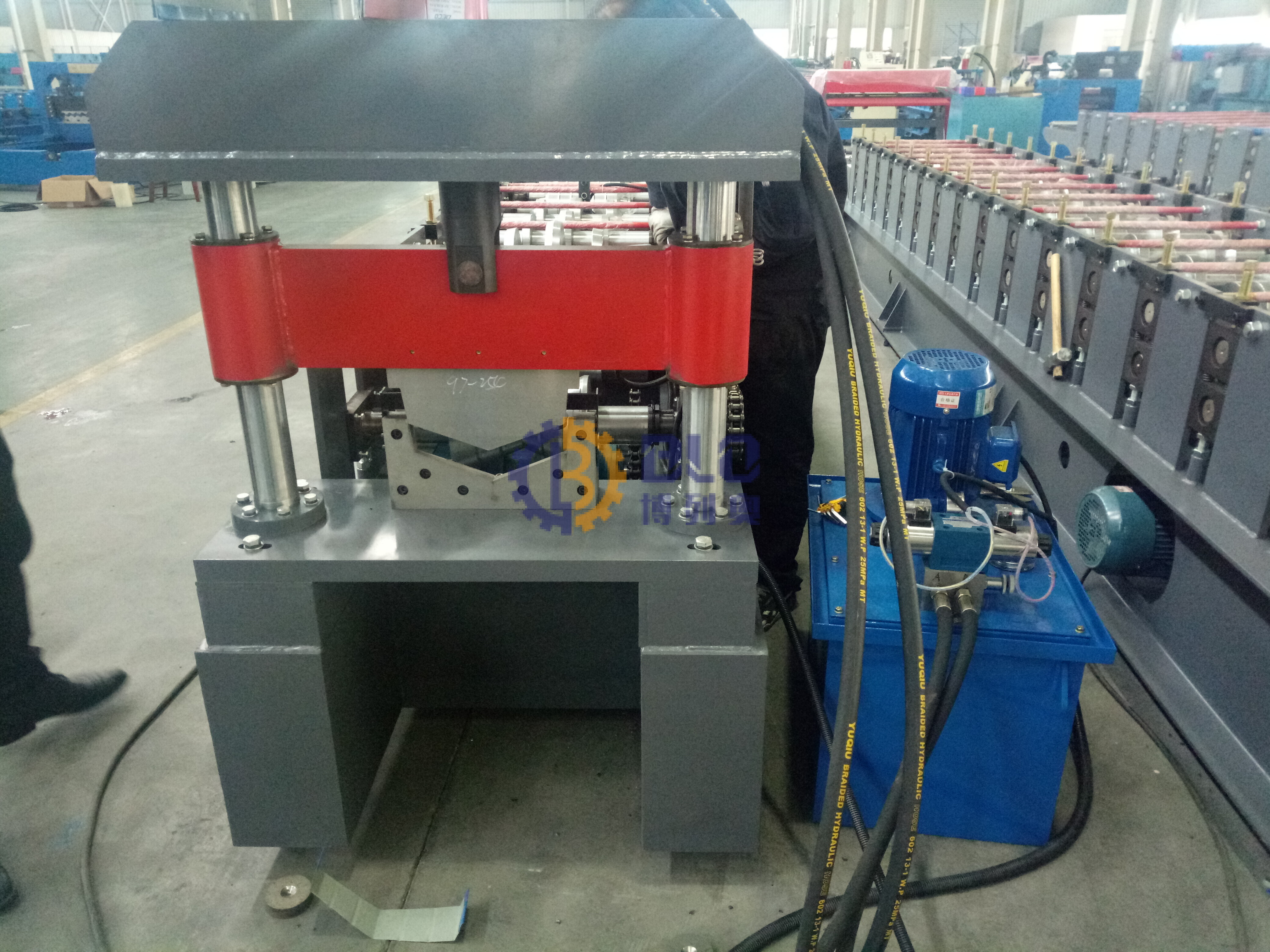

A Double Layer Roof Panel Roll Forming Machine is a specialized manufacturing equipment used to produce double-layer metal roof panels in a continuous roll-forming process. These panels are widely used in construction for roofing applications, offering enhanced durability, insulation, and weather resistance compared to single-layer panels.

Key Features of the Machine:

1. Double-Layer Panel Formation

- The machine forms two layers of metal sheets simultaneously, which may include:

Top Layer: Typically made of pre-painted galvanized steel, aluminum, or color-coated metal for weather resistance.

- Bottom Layer: Often made of galvanized steel or another protective layer for structural strength and insulation.

2. Roll Forming Process

- The machine uses a series of rollers and dies to gradually shape flat metal coils into the desired double-layer roof panel profile.

- The process is continuous, allowing for high-speed production with consistent quality.

3. Automatic Control System

- Modern machines feature PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for precise control over:

- Panel thickness

- Roll forming speed

- Cutting length

- Layer alignment

4. Hydraulic or Servo Cutting System

- Panels are cut to the required length using hydraulic shearing or servo-driven cutting for clean, burr-free edges.

5. Material Feeding & Uncoiling

- Equipped with dual decoilers to feed two separate metal coils (top and bottom layers) simultaneously.

- Some machines include automatic welding for coil joints to ensure uninterrupted production.

6. Insulation & Sealing Options

- Some double-layer roof panels have an insulating foam or air gap between layers for thermal and acoustic benefits.

- The machine may integrate adhesive application systems to bond the layers together.

Common Applications:

- Industrial & Commercial Roofing (factories, warehouses, airports)

- Cold Storage & Insulated Roofing (food processing plants, refrigerated warehouses)

- Residential Roofing (modern architectural designs)

- Agricultural Buildings (poultry farms, greenhouses)

Advantages of Double-Layer Roof Panels:

✔ Better thermal & sound insulation (reduced heat transfer)

✔ Higher strength & load-bearing capacity

✔ Improved weather resistance (reduces condensation)

✔ Aesthetic flexibility (different colors/textures for top and bottom layers)

Types of Double-Layer Roof Panels Produced:

- Standing Seam Roof Panels (hidden fastener systems)

- Corrugated Double-Layer Panels

- Sandwich Panels with Insulation Core

Latest Post

How To Work Downpipe Forming And Bending Integrated Machine2025-04-25

How To Work Downpipe Forming And Bending Integrated Machine2025-04-25 What is a ridge cap roll forming machine?2025-04-18

What is a ridge cap roll forming machine?2025-04-18 Custom Auto Stackers: Enhancing Efficiency in Material Handling2025-04-09

Custom Auto Stackers: Enhancing Efficiency in Material Handling2025-04-09 How Automatic Wire Mesh Welding Machines Boost Efficiency and Reduce Costs2025-04-07

How Automatic Wire Mesh Welding Machines Boost Efficiency and Reduce Costs2025-04-07 Downspout Roll Forming Machine in Gutter System2025-03-21

Downspout Roll Forming Machine in Gutter System2025-03-21

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!