01

PU foam Roll Shutters Slat Forming machine

PU foam 39mm 43mm roll shutter slat forming machine

The PU foam 39mm 43mm roll shutter slat forming machine is specialized equipment designed to produce insulated roller shutter slats with polyurethane foam cores. These machines are typically used for manufacturing slats of varying sizes, with 39mm being one of the standard widths. The process includes uncoiling, roll forming, polyurethane foam injection, and precision cutting.

Key features of these machines include:

High Efficiency: Machines can achieve speeds of 25–35 meters per minute.

Automated Operation: Fully automatic models are equipped with servo motor systems, automatic foam filling, and cutting for seamless production.

Customization: Machines can be designed to accommodate specific slat profiles or customer drawings.

Material: Suitable for PU foam and other insulated materials, offering enhanced thermal and acoustic insulation.

These machines are widely used in producing roll shutters for residential and commercial applications, providing privacy, insulation, and security.

55mm foam slat shutter roll forming machine

A 55mm foam slat forming machine is an industrial device designed to produce high-quality, insulated foam slats typically used in roller shutters, garage doors, and similar applications. These machines are engineered to handle materials like aluminum or steel sheets with polyurethane (PU) foam injected for insulation.

Material Compatibility: Suitable for aluminum or steel sheets, often with a thickness ranging between 0.28mm and 0.35mm, as well as PU foam for thermal and sound insulation.

Precision Engineering: Equipped with advanced rollers, forming stations, and cutting systems to produce slats with consistent dimensions and profiles.

Customization: Machines are often tailored to produce slats according to customer-specified profiles or drawings.

This equipment is critical for industries focused on manufacturing insulated roller shutters, contributing to energy efficiency and improved acoustic performance in buildings.

77mm foam Windows Shutters Insulated Slat Series Roll forming Machine

Working process:

Put the steel coil on the un-coiler→Guiding→Warm box(heaten the material)→ Roll-forming Machine→Injection machine → roll forming machine→Warm box(help expanding) →Adjusting device →Flying saw cutting→Run out table

Its applications include:

Commercial Security Shutters: These slats are essential in manufacturing durable security shutters used in shops, warehouses, and storefronts, providing robust protection and thermal insulation.

Garage Doors: The slats are commonly used in rolling garage doors, offering strength, noise reduction, and thermal insulation. These doors are typically installed in residential or commercial buildings.

Industrial Rolling Doors: They are employed in large industrial facilities where durability, ease of operation, and insulation are critical.

Thermally Insulated Shutters: The PU foam core provides excellent thermal insulation, making the shutters energy-efficient and suitable for environments requiring controlled temperature.

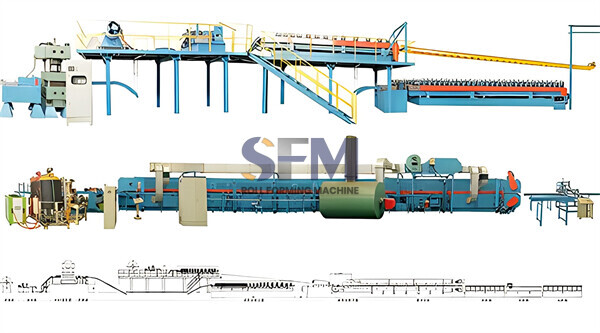

Garage Door PU foam Panel Production Line

Garage Door PU foam Panel Production Line made below includes the following parts: uncoiling system, film covering and cutting equipment, upper and lower embossing roller device, lower Corona system, roll forming system, reinforcing rib conveying, preheating oven, foaming system auxiliary device, five-component pentane high pressure foaming system, DBL conveyor, DBL heating, bandsaw system, stacker system, packing system and etc.

Working process:

Decoiling-------Film covering (flat plate cutting)--------Edge cutting-------Roll forming-------(Preheating material)-------PU Foaming------Laminating in double belt conveyor (heat preservation)-------Band cutting(dust absorption)------Conveyor rollers------Stacking-------Packing

02

Roll shutter door forming machine

Single Skin garage door panel line

A Single Skin Garage Door Panel Line is a specialized production line designed to manufacture single-layer panels for garage doors. These panels are created from materials such as pre-painted galvanized iron (PPGI) or galvanized sheets and are widely used in residential, commercial, and industrial applications.

Key Features:

Material and Thickness:Handles material thickness ranging from 0.3mm to 0.5mm. Uses materials like PPGI and galvanized steel.

Production Process:Equipped with uncoilers, roll-forming machines, and hydraulic cutters.

Production Process:Equipped with uncoilers, roll-forming machines, and hydraulic cutters. Produces panels with high precision and custom textures (e.g., woodgrain embossing) .

Panel Dimensions: Capable of producing panels in widths such as 400mm and 600mm.

Applications:Suitable for manufacturing lightweight, durable, and cost-effective garage doors where insulation isn't a priority.

These machines are ideal for high-speed, efficient production of durable single-skin garage door panels, meeting various design and size requirements.

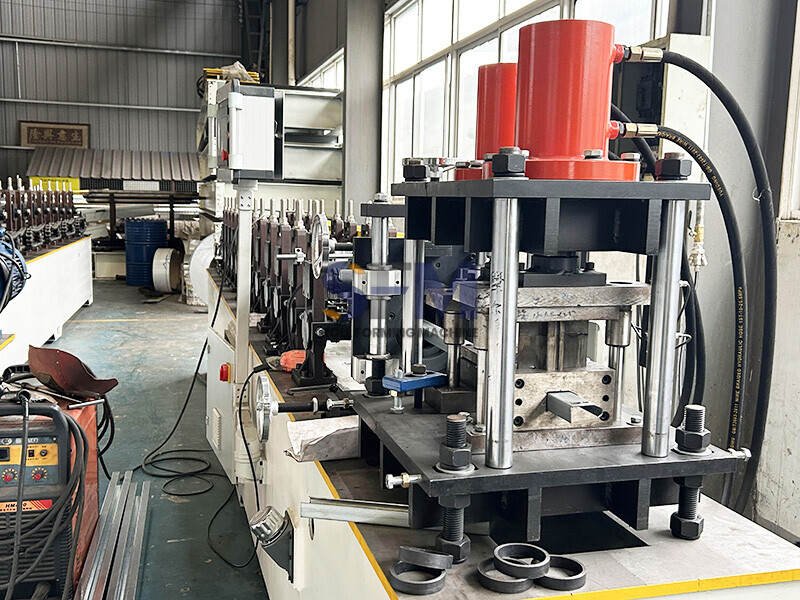

Double row windproof roller shutter door forming machine

The Double row windproof roller shutter door forming machine is a specialized device designed for manufacturing double-row windproof roller shutter doors. It plays a crucial role in the production of high-quality roller shutter doors that offer excellent wind resistance and durability.

Working Principle:

This machine operates on the principle of using a series of roller dies and transmission devices. It gradually bends and shapes metal sheets into the desired form of double-row windproof roller shutter door panels. The whole process is precisely controlled by a PLC control system, which adjusts the feeding speed of the metal sheets, the bending angle, and the forming dimensions with high accuracy, enabling fully automated production.

It is mainly used in the entrances and exits of industrial plants, warehouses, shopping malls, stores, garages and other buildings. It serves as a protective door against wind, theft and fire, providing safety protection for buildings.

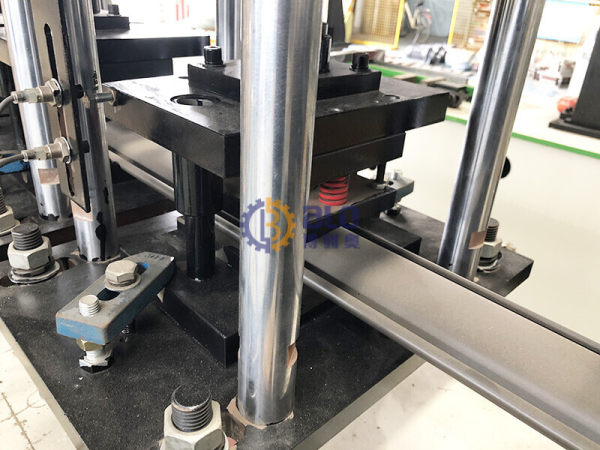

80mm/90mm roller shutter door forming machine

The 80/90mm roller shutter door forming machine is a specialized and efficient piece of equipment designed for the production of roller shutter doors with a thickness of 80mm or 90mm. It is widely used in the manufacturing of high - quality roller shutter doors for various applications, from commercial to industrial settings.

Structural Components:

Uncoiler: This component holds the large metal coil and releases the sheet material at a controlled speed, ensuring a steady supply of raw material for the forming process.

Roller Die Set: The heart of the machine, the roller die set consists of multiple pairs of rollers. Each pair is designed to perform a specific stage of the shaping process. The rollers are made of high - quality alloy steel, hardened to ensure long - term wear resistance and accurate shaping.

Cutting Device: Once the slat is formed to the desired length, a high - precision cutting device, such as a hydraulic shear, cuts the slat from the continuous sheet. This device can be adjusted to produce slats of different lengths according to production requirements.

Control System: Equipped with an advanced PLC (Programmable Logic Controller) control system, the operator can easily set parameters such as production speed, slat length, and the number of slats to be produced. The control system also monitors the entire production process, providing real - time feedback and ensuring stable operation.

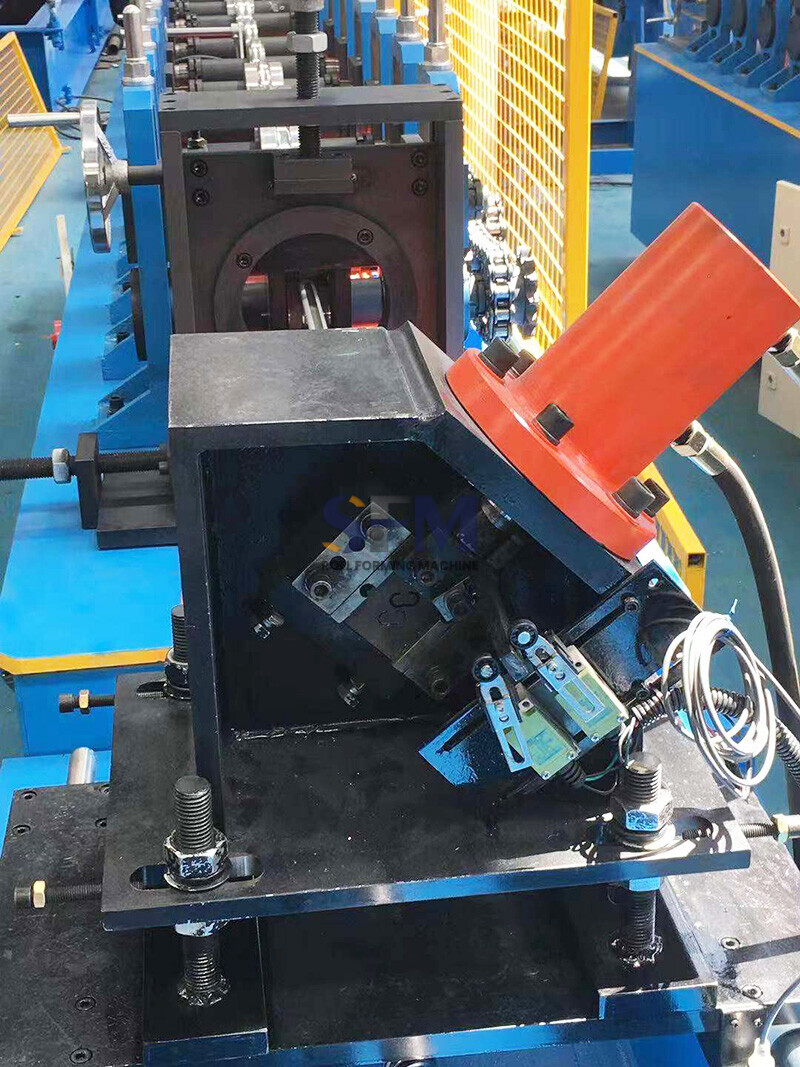

Track rails 2in roll forming machine of shutter door

The "Track rails 2in roll forming machine of shutter door" is a specialized piece of equipment designed for manufacturing 2-inch track rails used in shutter doors. It plays a vital role in the production process of shutter doors, ensuring the smooth operation and reliable performance of the doors.

Working Principle:

This roll forming machine operates based on the principle of using a series of rollers and forming mechanisms. A metal strip is fed into the machine, and as it passes through the successive rollers, it is gradually bent and shaped into the specific profile of a 2-inch track rail for the shutter door. The entire process is precisely controlled to ensure the accuracy and consistency of the track rail's shape and dimensions.

Performance Characteristics:

High Precision: It can produce 2-inch track rails with high dimensional accuracy, ensuring that the track rails fit perfectly with the shutter doors and enabling smooth opening and closing of the doors.

High Production Efficiency: With its continuous roll forming process and efficient cutting mechanism, the machine can produce a large number of track rails in a short time, meeting the production needs of different scales.

Stable Performance: The machine is made of high-quality materials and advanced manufacturing processes, ensuring its stability and reliability during long-term operation. It can withstand high working pressures and has a long service life.

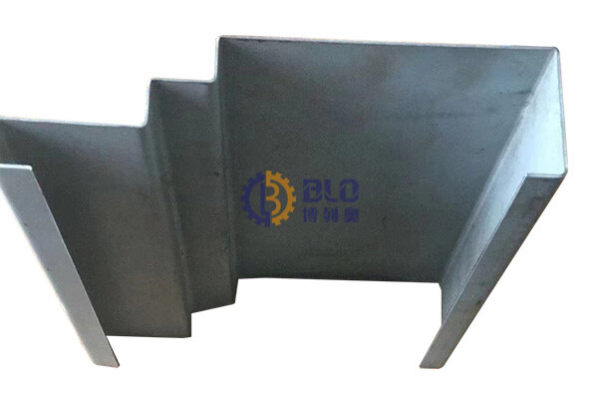

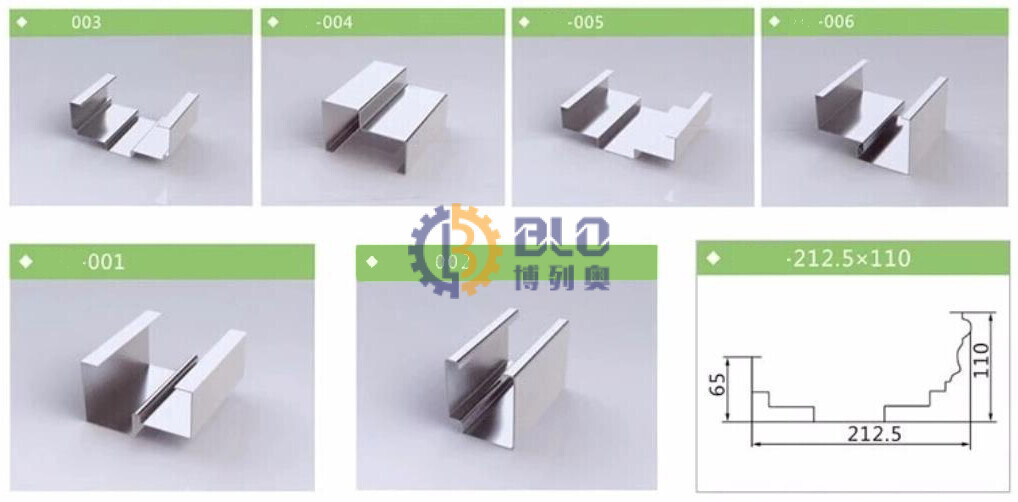

Shutter box roll forming machine

A shutter box roll forming machine is an advanced mechanical device designed for manufacturing shutter boxes with high precision and efficiency.

Here is a detailed introduction:

Working Principle : It operates based on the roll forming principle. The machine consists of a series of rollers arranged in sequence. As the metal coil is fed into the machine, the rollers gradually shape the metal sheet into the desired profile of the shutter box through a series of bending and rolling operations.

Feeding System: It includes a coil holder and uncoiler to supply the metal coil smoothly.

Roll Forming Unit: Comprises multiple sets of rollers, precisely designed and machined to ensure accurate shaping.

Cutting System: Equipped with a cutting device, such as a flying shear, to cut the formed shutter box to the required length.

Control System: Usually a PLC control system, enabling precise control of the machine's speed, operation sequence and other parameters.

03

Door frame roll forming machine

Door Frame Roll Forming Machine

A Door Frame Roll Forming Machine is a specialized industrial system designed to manufacture metal door and window frames from materials like steel, aluminum, or bronze. These machines automate the process of creating precise, durable frames in various dimensions and styles for residential, commercial, and industrial applications.

Key Features:

Material Compatibility:Works with pre-painted, PVC-coated, galvanized, and plain steel sheets .Can produce frames for fire-rated doors, steel doors, and other designs.

Components:Includes a decoiler, leveling device, roll-forming system, hydraulic cutter, and run-out table.

Production Efficiency:Automated systems ensure clean, precise 90° and 45° cuts, with customizable widths (e.g., 120–250mm) .Reduces manual labor, enhancing productivity.

Applications:Ideal for manufacturing door frames for interior and exterior use in homes, offices, and industries.

These machines are highly versatile, enabling the production of multi-width and complex profiles to meet various customer demands.

Safety door and Window roll forming machine

A door frame roll forming machine is a specialized piece of equipment in the metal processing industry, mainly used for manufacturing door frames with high efficiency and precision.

The following is an introduction to it:

Working Principle:It works on the principle of roll forming. The machine typically has a series of roller sets. When the metal strip is fed into the machine, it passes through these roller sets in sequence. Each set of rollers gradually bends and shapes the metal strip until it forms the final door frame profile.

Applications:It is widely used in the production of door frames in the construction industry, suitable for various types of doors, including residential doors, commercial doors, and industrial doors. It is also used in metal processing plants and door manufacturing factories to meet different production needs.

Door frame making machine

A Door Frame Roll Forming Machine is a specialized system used to manufacture metal door and window frames, commonly for residential, industrial, and commercial buildings. These machines automate the process of shaping, cutting, and assembling metal sheets into precise door or window frame profiles.

Features and Functions:

Material Handling:Compatible with steel, aluminum, and bronze materials, including pre-painted or PVC-coated sheets.

Key Components:

Decoiler:Unwinds the raw material rolls.

Feeding and Leveling System: Ensures smooth material feeding.

Roll Forming System: Shapes the material into the desired profile.

Hydraulic Post Cutting: Ensures accurate 90° and 45° cuts.

Customization:Can produce multi-width profiles (e.g., 120-250 mm width) based on regional standards.

Applications:

Used to produce fire-rated door frames, steel window frames, and other types of frames with high precision and durability.

Benefits:

Enhances productivity and reduces labor costs. Provides high accuracy and consistent quality. Can handle high-volume production efficiently.

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!