01

Steel Metal Floor Deck roll forming machine

Full Automatic Steel Metal Floor Deck roll forming machine

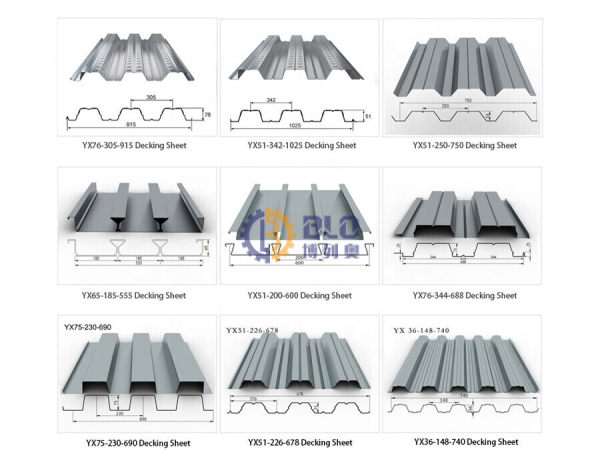

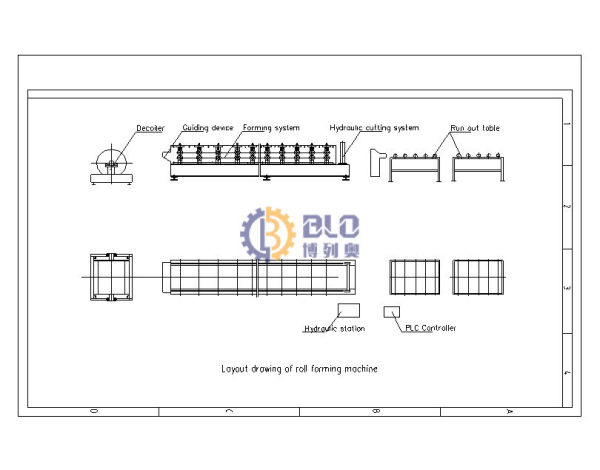

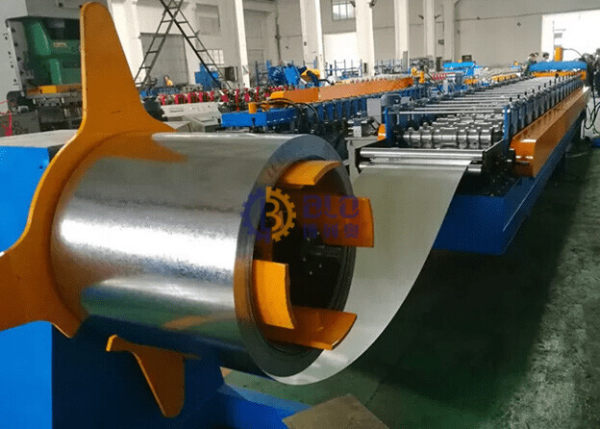

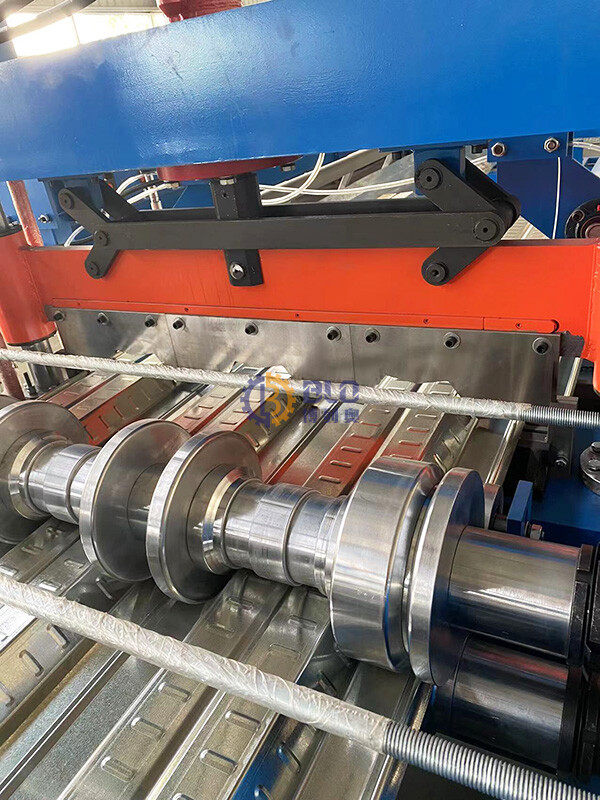

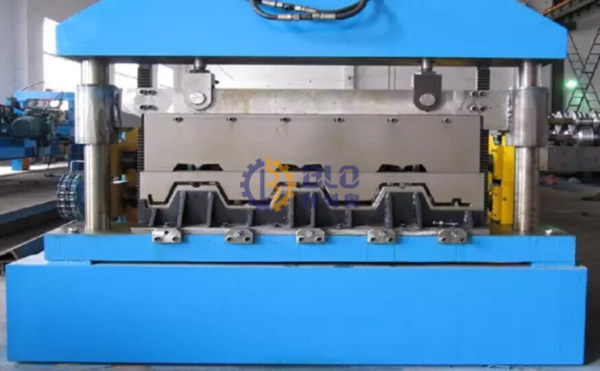

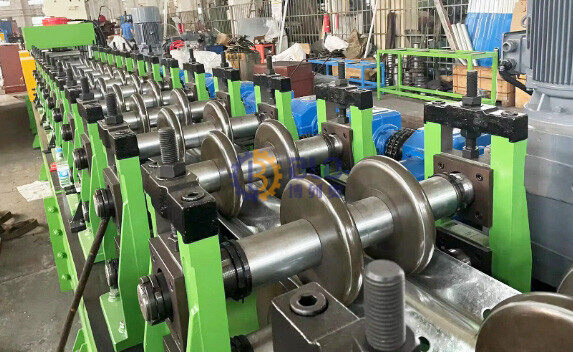

Our YX50-180-900 floor deck roll forming machine consists of decoiler, feeding and levelling device, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

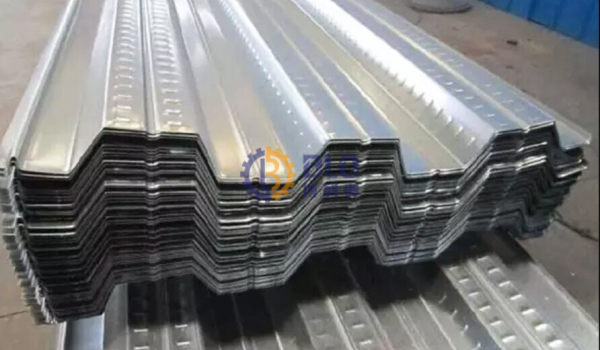

Galvanized steel floor decking sheet roll forming machine

Floor deck roll forming machine is a specialized piece of equipment used to manufacture metal floor decking sheets. These sheets are crucial components in construction, particularly in building floors for commercial and residential structures. The machine shapes and forms metal coils into floor deck profiles that provide support and strength for concrete slabs in composite flooring systems

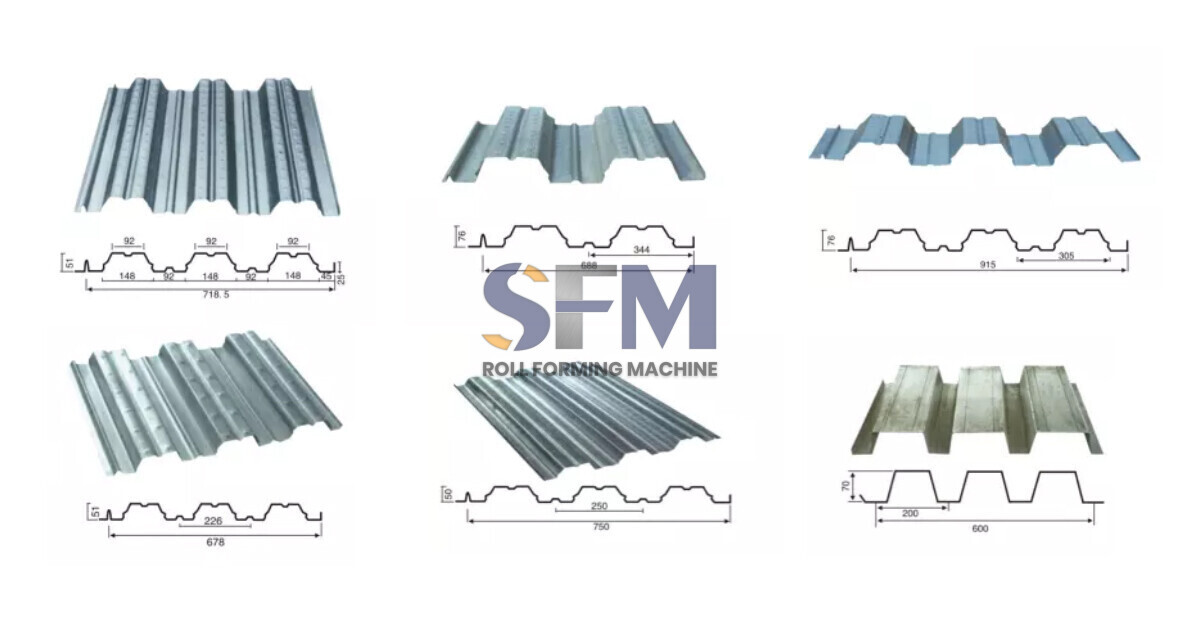

B-Decking Building Roll Forming Machine

Profile: A common metal deck profile with a "B" shape that provides strength and ease of concrete bonding. Ideal for residential and commercial buildings.

Common Thickness: 0.7mm to 1.2mm.

Applications: Used in both flooring and roofing applications.

Metal Floor Deck Roll Forming Machine Metal Deck sheet Making Machine

Machine Weight:These machines are typically heavy, ranging from 12 to 22 tons, depending on the size and complexity of the system (cunmac.com).

Roller Stations:The number of roller stations can vary from 24 to 40, with each station progressively shaping the metal into the final profile.

Material Thickness:Metal sheets used can range from 0.7mm to 1.5mm, depending on the requirements of the building project and the specific deck type (lotosforming.com).

Power Supply:Most floor deck roll forming machines operate on 480V, 3-phase, 60Hz power, ensuring they have sufficient power to operate smoothly and efficiently.

Production Speed:Depending on the design and configuration, these machines can produce metal deck sheets at speeds ranging from 5 to 15 meters per minute.

Metal Galvanized Floor Deck Forming Machine

A floor deck roll forming machine is an essential tool in modern construction, providing cost-effective, precise, and efficient production of floor decking sheets. The choice of machine depends on factors like material type, deck profile, and production speed, with key considerations being the number of roller stations, power requirements, and the level of automation. As demand for high-performance, reliable decking solutions grows, the quality and versatility of these machines continue to evolve.

02

Highway Guardrail Building

With Punching Roll Forming Machine

Side Rail Guard Roll Highway Guardrail Building With Punching Roll Forming Machine

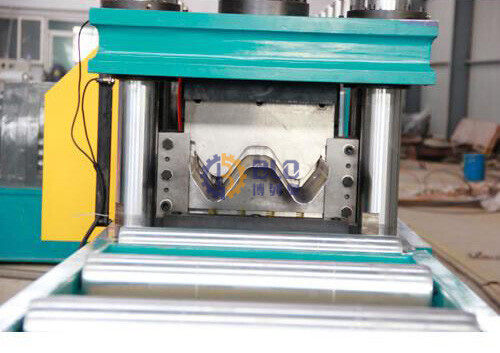

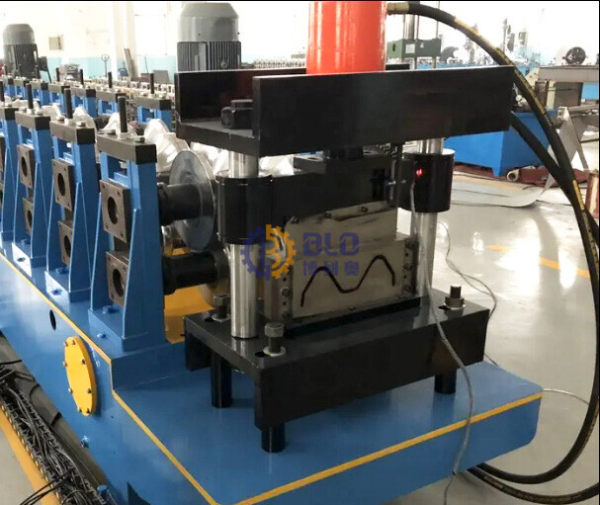

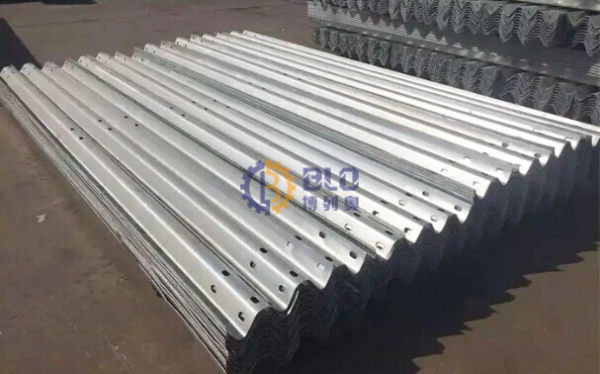

Highway guardrail forming machine is specialized equipment used to produce various types of highway guardrails or crash barriers. These machines utilize a roll forming process to create metal beams that are typically installed along highways for safety purposes. The most common types of guardrails produced are W-beam, thrie-beam, and other wave profiles that help in absorbing impact and redirecting vehicles safely.

Two And Three Waves Crash Barrier Robust High Way Guard Rail Stable Road

A guardrail forming machine is a type of roll forming machine used to manufacture W-beam and thrie-beam highway guardrails. These are usually made of steel, with coatings such as galvanized steel for durability and corrosion resistance. The machine takes flat steel coils and shapes them into the required guardrail profile through continuous bending, cutting, and rolling processes.

2mm-4mm Thickness W Beam Highway Road Crash Barrier Guardrail Roll Forming Machine

W-beam Guardrails: The most common type, these have a "W" shape and are used in many countries around the world. W-beam guardrails are often made from galvanized steel for enhanced durability.

Thrie-beam Guardrails: These are more rigid and are often used in more hazardous environments such as curves, bridges, or areas with high-speed traffic.

03

Galvanized Cable Tray and

Retail Shelf Panel roll forming machine

Metal Perforation Auto Changeable Galvanized Cable Tray Roll Forming Machine

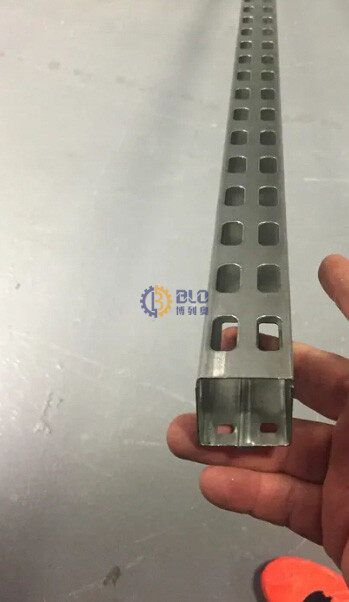

Fully Automatically Width Adjustable Perforation Ladder Type Cable Tray Roll Forming Machine is a specialized piece of machinery used to produce cable trays. These trays are primarily used in industrial settings for organizing and supporting electrical cables. The machine performs several critical functions, including perforation (punching holes), forming the ladder-like structure, and adjusting the width of the tray to meet specific requirements.

Fully Automatically Width Adjustable Perforation Ladder Type Cable Tray roll Forming Machine

This machine is designed for automation, which means it reduces the need for manual intervention during production. It operates autonomously, taking raw materials such as galvanized steel and converting them into the finished cable trays without manual adjustments or monitoring.Automation improves production speed, consistency, and safety by minimizing human error.

0.6-1.0mm Thickness Retail Shelf Panel roll forming machine

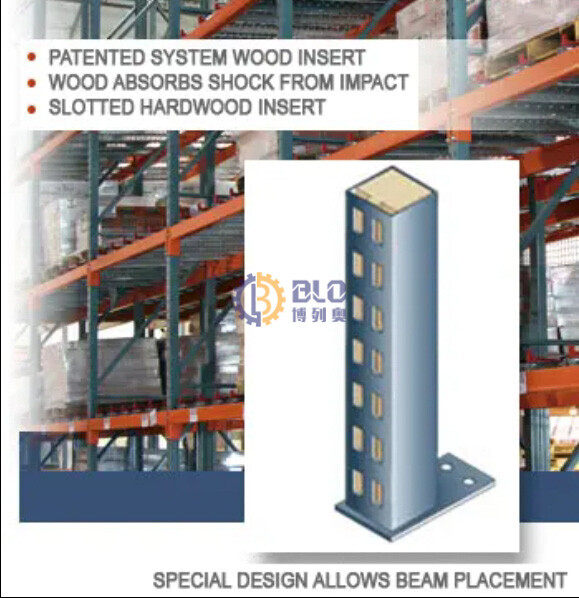

Storage racking forming machine is a specialized piece of equipment used in the manufacturing of storage racks for various industrial and commercial applications, such as warehouses, workshops, and retail spaces. These machines play a vital role in producing the structural components of storage systems, typically made from steel or other metals, by roll forming, punching, cutting, and bending metal sheets. These components often include beams, uprights, and shelves, which are then assembled into shelving or racking systems.

Adjustable Width 350-600mm Supermarket Shops Shelf Pallet Rack Roll Forming Machine

Storage racking forming machines are essential tools in the production of industrial storage systems, particularly in warehouses and logistics centers. They offer automation, efficiency, and high precision, making them invaluable in manufacturing a wide range of racking components. Whether producing uprights, beams, or complete shelving systems, these machines streamline production and contribute to cost savings, while providing customizable solutions for various storage needs.

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!