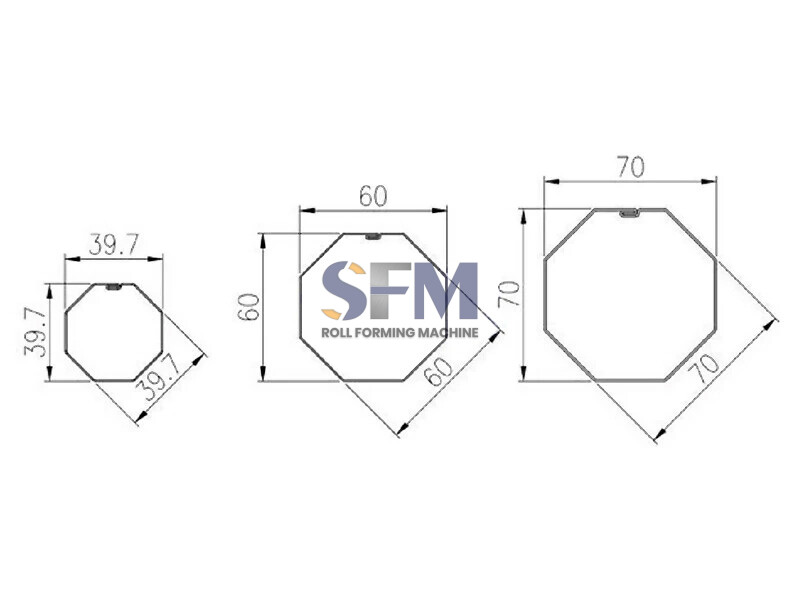

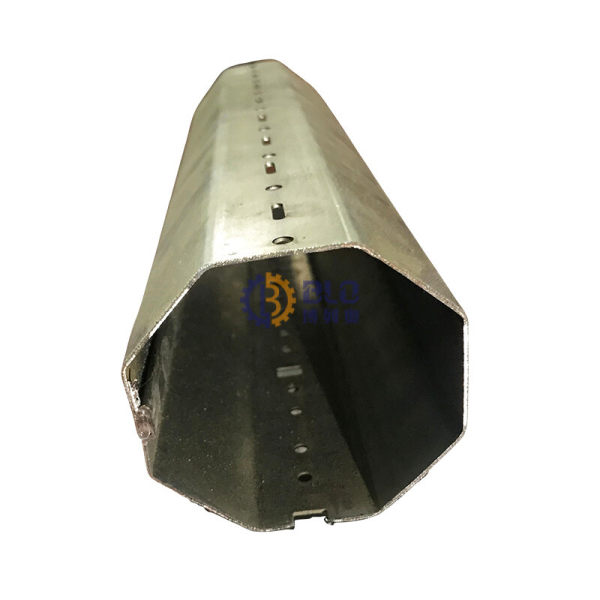

Octagonal tube roll forming machine

Size : 40mm,60mm,70mm,180mm

An octagonal tube roll forming machine is specialized equipment used to manufacture octagonal pipes, primarily for applications such as rolling shutter door systems. These pipes serve as the structural axes for shutter slats, enabling smooth and efficient operation.

Key Features:

Material and Thickness: Designed to handle materials like galvanized steel with a thickness range of 0.4-1.2 mm.

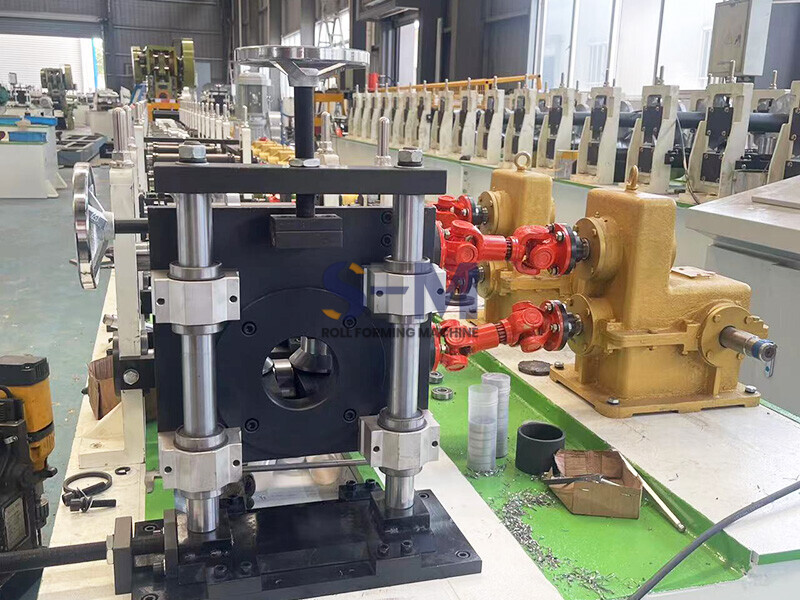

Drive System: Utilizes a gear transmission system for stable and efficient operation.

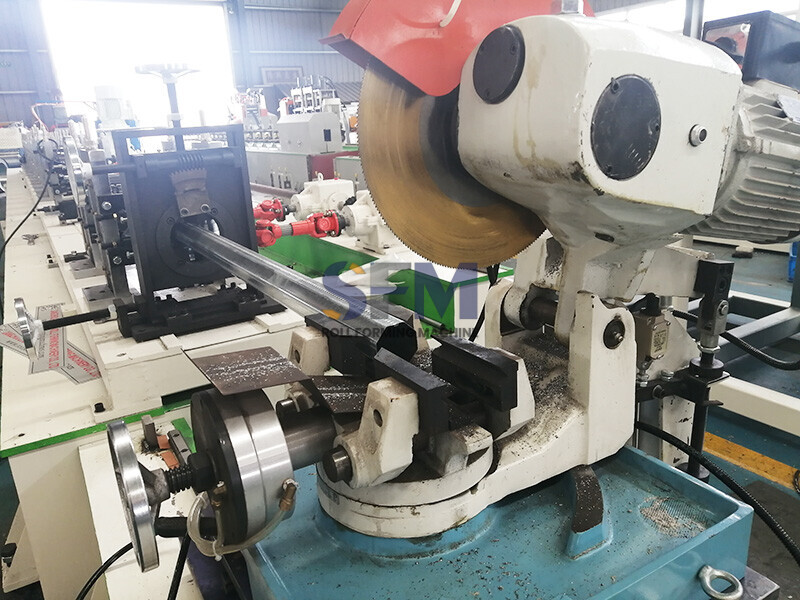

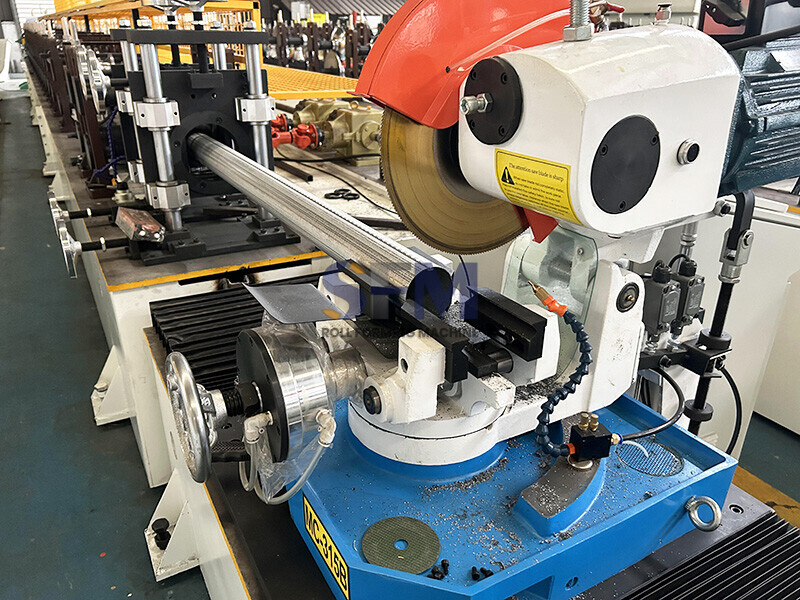

Cutting Mechanism: Includes fly saw cutting systems operated by servo motors for precise and efficient cutting of tubes.

Forming Stations: Equipped with up to 20 forming stations for high-precision shaping.

Speed and Power: Features forming speeds of 8-15 meters per minute and powered by a 7.5 kW main motor.

Applications: Suitable for creating axes used in roller shutter doors, ensuring the production of durable and standardized components .

This machine is highly efficient, customizable, and reliable for industries requiring octagonal tubes in large volumes.

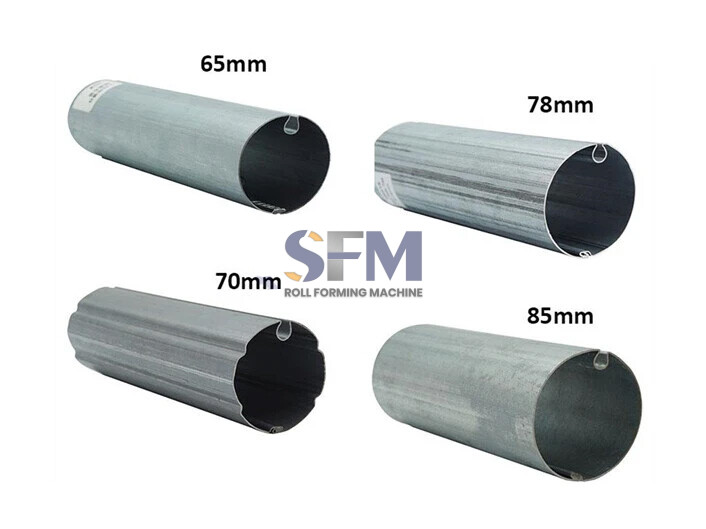

Round tube roll forming machine

A round tube roll forming machine is used to produce round tubes or pipes for various industries, including construction, furniture, automotive, and more. These machines form tubes from raw materials such as carbon steel, stainless steel, or galvanized steel using a roll forming process.

Key Features:

Material Compatibility: Handles materials like stainless steel, carbon steel, and other metals. Thickness varies depending on the machine and application.

Production Speed and Efficiency: Machines are designed for high-speed and continuous production, ensuring uniformity and precision in tube shape.

Automation: Equipped with PLC-controlled systems for automated operation and precise adjustments during production.

These machines are robust, customizable, and designed for high-volume tube manufacturing.

Awing tube roll forming machine

Awing tube roll forming machine is used for manufacturing the octagonal or round pipes that serve as the axles for rolling shutter doors. These pipes are essential components that allow the shutter door slats to roll up and down smoothly.

Key Features:

Pipe Material and Thickness: Machines typically handle materials such as galvanized steel or mild steel, with thickness ranging from 0.4mm to 1.2mm depending on the specifications.

Design: These machines are specifically tailored to produce octagonal or round pipes used in rolling shutters for residential, industrial, and commercial applications.

Components: Features include gear transmission systems, forming stations (e.g., 20 stations), and optional fly saw cutting for precision.

Speed and Productivity: High-speed machines with efficient setups allow for the production of pipes with a consistent and uniform finish.

These machines are ideal for manufacturers of rolling shutters, enhancing efficiency and reducing costs in shutter door production.

Welded Tube Production Line

Industry Stainless Steel Tube Prodcution Line

Industry Stainless Steel Tube Production Line is designed for manufacturing stainless steel straight welded pipe for construction, transportation, metallurgy , and machinery and vehicle industries. It adopts long steel strip as the material to manufacture steel pipes according to requested size by cold rolled forming and argon arc welding method. To be specific, the stainless steel pipe production line can produce round pipe, square and rectangular tube, as well as section steel through cold rolled forming and TIG welding technology.

Tube Sizes:

Production Process:

Raw material → Uncoiling → cut and butt welding → Accumulator → Leveling → Forming → TIGwelder→ Cooling → Polishing → Sizing →Annealing→Straightening → Fixed length cutting → Finished pipe collecting

Details of several parts wholes line:

Uncoiler

Function: support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum, brake.

There are 3 types: pneumatic, hydraulic and manual.

Strip Accumulator

Function: storage strip to keep continue production.

2 Types: Horizontal / Vertical

Forming Section

Function: forming the tube from strip.

Advantage:

A.Advanced forming technical

B.One-stage molding platform

C.Reliable quality gear box

D.Siemens Beide motor

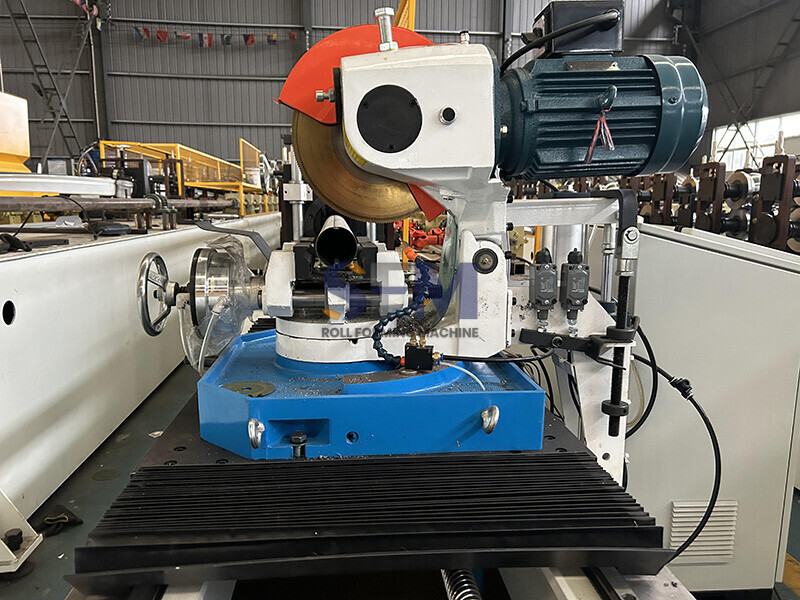

Flying saw / Cold Saw

Function: cutting the tube mill line tube to right length.

Fly saw: easy to operation, low investment.

Cold saw: no noise, no burr cutting precision and cross section.

Advantages of production line :

1.Easy and safe to operate;

2.low maintenance, and cost reduction, reducing and high production;

3.One time for production of stainless steel pipe, which allows flatting, forming, welding, annealing, polishing, sizing, straightening, finishing, cutting, and unloading.

Square Pipe Production Line

Forming machine use cold roll forming direct rolled into square type, adopt multi-point forming technology. The material deformation of each stands changes from original line touch to point touch, reduce the friction and improve products surface quality, improve the electric efficiency. Roller position adjustment is automatic. One set of roller is able to adapt for full kinds of tube sizes.

PLC control, do the size adjustment automatically. Only need to input the production specification, the roller will be adjusted to the right position automatically.The main drive of forming sizing machine adopts multi-motor single drive mode, and adopts one motor to drive one horizontal roller stand, which Can be precisely adjusted to make the speed match between the stands, reduce the speed difference, and make the product not scratched. Select DC motor, convenient and reliable maintenance.

Production Process:

Material Feeding:The metal coil is loaded onto the uncoiler and fed into the production line.

Leveling and Straightening:The material passes through a leveling unit to ensure it is flat and free of deformities.

Roll Forming:The metal strip is gradually shaped into a square profile by passing through a series of roll stands.Each stand contributes to the final shape, with the profile becoming more defined at each stage.

Welding (if applicable):For square tubes, the edges of the formed strip are welded together using high-frequency welding.

Sizing and Calibration:The square profile is precisely sized and calibrated to meet dimensional tolerances.

Cutting:The continuous square profile is cut into specific lengths as required.

Finishing:The finished square profiles are inspected, stacked, and prepared for packaging.

Material Feeding & Leveling and Straightening

Roll Forming

Welding (if applicable) & Sizing and Calibration

Square Pipe sizes:

Advantages of Cold Roll Forming for Square Profiles:

High Precision: Ensures consistent dimensions and high-quality square profiles.

Efficiency: Continuous production process reduces material waste and increases output.

Versatility: Can produce various sizes and thicknesses of square profiles.

Cost-Effective: Suitable for large-scale production with minimal material loss.

Applications:

Construction (structural frames, supports).

Automotive (chassis components).

Furniture (frames, legs).Industrial equipment (racks, enclosures).

High-frequency Welding Tube Productionl Line

The high-frequency welding tube mill line is engineered to produce round, square, and rectangular pipes with exceptional precision and quality. Utilizing advanced roll pass design, this production line ensures superior machining quality and high-precision assembly, making it ideal for manufacturing welded steel pipes that meet stringent standards.

Produciton Sizes:

Steel Strip Specification

Production line process flow:

Raw material (strip coil) → uncoiling → shearing butt welding → spiral looper → feeding forming → high frequency welding → deburring → cooling water jacket → sizing and straightening → flying saw cutting → blanking (manual stacking and wrapping) )→Inspection→Warehousing

Key Features of the Process:

High Efficiency: Continuous production with minimal downtime.

Precision: Advanced roll forming and sizing ensure tight tolerances.

Versatility: Capable of producing round, square, and rectangular tubes.

Durability: High-frequency welding creates strong, reliable welds.

This production process is widely used in industries such as construction, automotive, furniture, and industrial equipment for manufacturing high-quality welded tubes. Let me know if you need further details!

Special-shaped Custom Profile Forming Machine

A Special-shaped Custom Profile Forming Machine is a type of industrial equipment designed to manufacture custom-shaped metal or material profiles. These machines are used to produce complex, non-standard shapes that cannot be achieved with standard rolling or extrusion processes. They are commonly used in industries such as construction, automotive, aerospace, and manufacturing, where unique profiles are required for specific applications.

Key Features of Special-shaped Custom Profile Forming Machines:

Customization Capabilities:Able to produce profiles with unique shapes, curves, and dimensions based on customer requirements.Suitable for creating irregular or asymmetrical profiles.

Material Versatility:Can work with various materials, including steel, aluminum, copper, and other metals, as well as composite materials.

High Precision:Equipped with advanced CNC (Computer Numerical Control) systems to ensure accurate and consistent shaping.Allows for tight tolerances and repeatability.

Flexible Forming Process:Utilizes roll forming, bending, stamping, or other forming techniques to achieve the desired profile.Can handle both small and large production runs.

Automation:Often integrated with automated systems for material feeding, shaping, cutting, and stacking to improve efficiency.

Adjustable Tooling:Features interchangeable or adjustable dies and rollers to accommodate different profile designs.

Energy Efficiency:Designed to minimize energy consumption while maintaining high productivity.

Applications:

Construction: Producing custom metal profiles for architectural elements, roofing, cladding, and structural components.

Automotive: Manufacturing specialized parts for vehicle frames, chassis, and body panels.

Aerospace: Creating lightweight, high-strength profiles for aircraft components.

Furniture: Designing unique metal frames or decorative elements.

Industrial Equipment: Producing custom profiles for machinery, conveyor systems, and enclosures.

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!