01

Uncoiler Machine

An uncoiler is a vital piece of equipment in metal processing lines, such as roll forming, stamping, slitting, and cutting lines. Its primary purpose is to handle and uncoil steel coils to prepare them for the next production processes.

Key functions of a steel uncoiler include:

Supporting the Steel Coil: The uncoiler tightens the inner hole of the steel coil to securely hold it during operations.

Unrolling the Coil: The uncoiler rotates to release the steel strip and delivers it to the next process (e.g., slitting or leveling).

Tension Control: It maintains tension in the steel strip to ensure smooth feeding into downstream machines.

BlO Machinery can offer different series uncoiler machines based on customizes’ requirements.Uncoilers, also known as decoilers, are classified based on their structure, functionality, and power source.

Below are the main types of uncoilers:

Based on Structure:

Single Mandrel Uncoiler:Consists of a single mandrel for holding and uncoiling a single coil.

Double Mandrel Uncoiler:Has two mandrels, allowing for faster coil changes and reduced downtime.

Based on Power Source:

Manual Uncoiler:No power source, operated manually.

Electric Uncoiler:Equipped with a motor to automate coil feeding.

Hydraulic Uncoiler:Uses hydraulic systems for heavy-duty operations and better tension control.

About loading capacity ,BLO machinery can offer 2ton,5ton,10ton,15ton,20ton.

02

Palletizing system / Stacking system

The palletizing system of a roll forming machine is an automated or semi-automated process designed to handle, stack, and organize the finished products from the roll forming line. It ensures efficient handling of the formed material.Usually BLO Machinery can offer two types of palletizing systems: side shifting and lengthwise. Customers can choose which design to use based on their actual plant.

Key Features:

Automated Handling: Finished components, such as tile panels and corrugated sheets for roof industry, are stacked and organized systematically.

Flexibility: Systems can handle different sizes and patterns, with adjustable lengths to accommodate multi-size products.

High-Speed Integration: Palletizing machines are designed to work seamlessly with high-speed roll forming production lines to avoid bottlenecks.

By automating the palletizing process, manufacturers can achieve greater efficiency, consistent quality, and reduced labor costs.

03

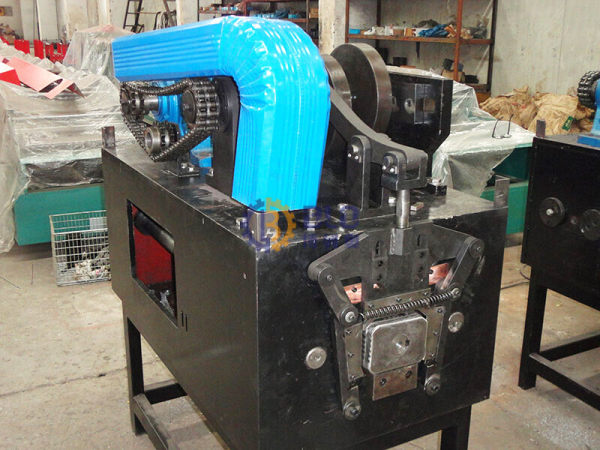

Embossing machine

An embossing machine for steel is specialized industrial equipment designed to create patterns, textures, or imprints on steel sheets or plates. These machines are commonly used in industries such as construction, automotive, and decorative metalworking.

Customizable Patterns: Embossing machines press patterns onto steel sheets using upper and lower rollers. The design can be customized based on the width and specifications of the sheet.

06

Punching machine

Punching machine has a tilting casting structure, which makes it easier for stamping parts or waste to slide off the die when tilted. It uses a rigid key clutch with single and continuous operation specifications. It uses a band brake, and the slide is equipped with a collapse-type safety device. When overloaded, the safety device is collapsed, thereby ensuring that the entire machine is not damaged.

07

Seaming Machine

A seaming machine for a shutter door is a specialized piece of equipment used in the manufacturing or repair of roller shutter doors. These machines are designed to join or seam the edges of the shutter door slats (typically made of aluminum, steel, or other materials) to create a continuous, durable, and flexible curtain.

Key Features of a Seaming Machine for Shutter Doors:

Material Compatibility: Designed to work with materials like aluminum, steel, or PVC used in shutter door slats.

Seaming Process: Joins the edges of the slats to form a tight, interlocking seam that allows the door to roll smoothly while maintaining strength and durability.

Adjustability: Can be adjusted to accommodate different thicknesses and widths of shutter slats.

Precision: Ensures precise alignment and seaming for smooth operation of the shutter door.

Portability: Some machines are portable for on-site repairs or installations.

Types of Seaming Machines:

Manual Seaming Machines: Operated by hand, suitable for small-scale repairs or custom jobs.

Automatic Seaming Machines: Used in large-scale production, offering higher efficiency and consistency.

08

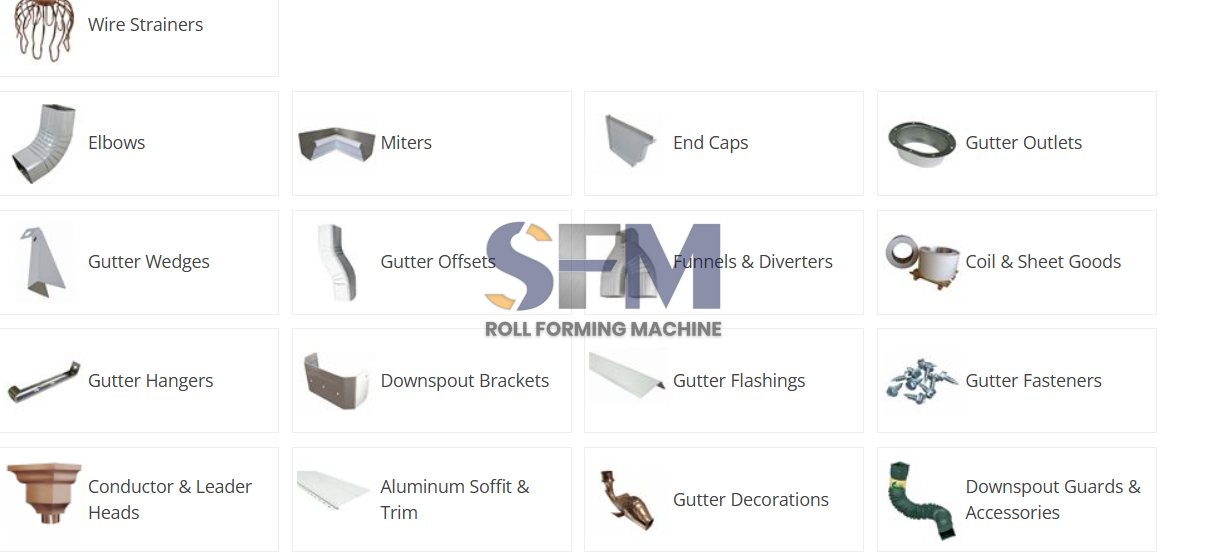

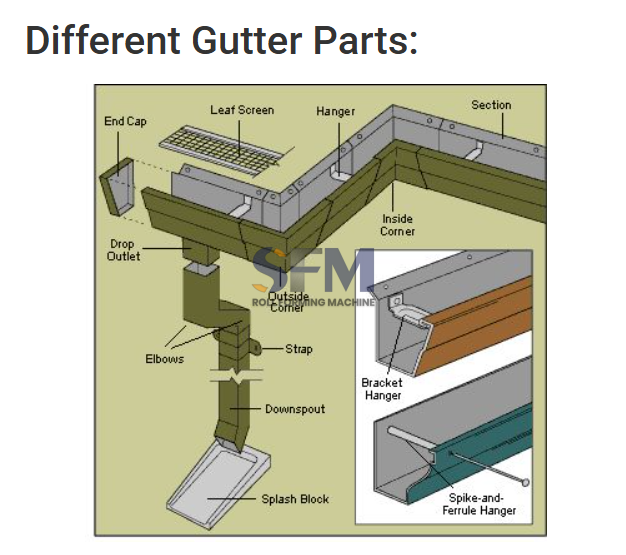

Gutter Accessories For Gutter Systems

While gutter systems are simple, they are made up of many different moving parts that help the gutter system work at max efficiency. Gutters function as your outdoor plumbing. It’s essential to mitigate that rainwater away from the foundation of your home and roof. Read on to learn what the different components of a gutter system are.

Gutters

There are a variety of different types of gutters. The most popular design for gutters is k-style, half-round, and box style gutters. Gutters exist in many colors, materials, sizes,and shapes. Gutters are fabricated in two ways: seams and seamless.

Downspouts

A downspout is a fully enclosed vertical pipe that runs along the vertical edges of your home and meets the end of a gutter section. The role of a downspout is to channel the water collected by your gutters and dispose of it on the ground level, away from your home’s foundation.

Elbow

The last part of your gutter system from top to bottom is the “Elbow,” which is the bent metal (typically aluminum) attached to the end of your downspout.Your elbow connects to the vertical downspout and channels water away from your home’s foundation onto a splash block.

End Cap

Your seamless gutter runs are shaped like a trough that come in 5″ and 6″ sizes. However, at the end of a run, where the water exits using the downspout, there are end caps made of metal to seal the gutter run. These end caps are also caulked with gutter caulk.

Hidden Gutter Hanger (Screw-in)

Old school gutter spikes have been replaced with screw-in hidden hangers that clip to the front of your gutter (often K-style aluminum gutters) and then are screwed into your fascia board along the back side of your gutter runs.

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!