01

PU and Rock Wool Composite Panel

PU (polyurethane) rock wool composite panels combine the advantages of polyurethane and rock wool insulation. They are commonly used in construction projects requiring high performance in fire resistance, thermal regulation, and durability.

Structure

These panels typically have three layers: an external and internal sheet (galvanized or aluminum) and a core layer of rock wool insulation. The edges are often sealed with polyurethane for enhanced stability and durability.

Fire Resistance

Rock wool is inherently non-combustible, giving these panels excellent fireproof properties. PU edge sealing further improves safety by protecting the core from exposure to external elements.

Thermal and Acoustic Insulation

The rock wool core provides superior thermal insulation and soundproofing, making these panels ideal for environments with stringent energy efficiency or noise control requirements.

Applications

These panels are used for walls, roofs, and partitions in industrial buildings, warehouses, and cold storage facilities.

Environmental Benefits

PU edge sealing reduces environmental impact by improving energy efficiency and extending panel lifespan.

1. The outer steel plate of the panel is corrugated.

2. The effective width of the panel is 1000mm.

3. The thickness of the panel can be 40mm, 50mm, 60mm, 75mm, 80mm, 100mm according to the regional environment and design requirements.

4. This panel type can be used as PUR/PIR polyurethane series insulation panel, and can also be used as rock wool series (polyurethane end-capped, pure rock wool) fireproof panel.

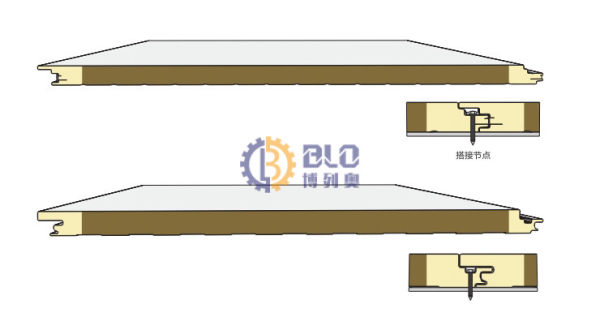

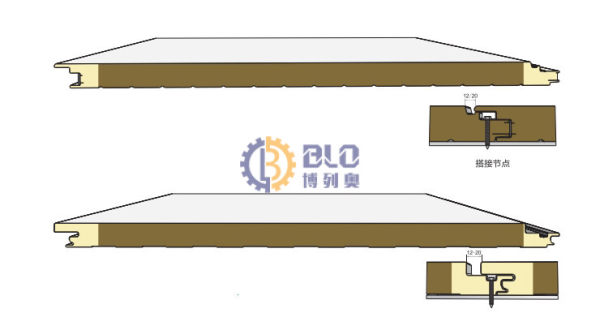

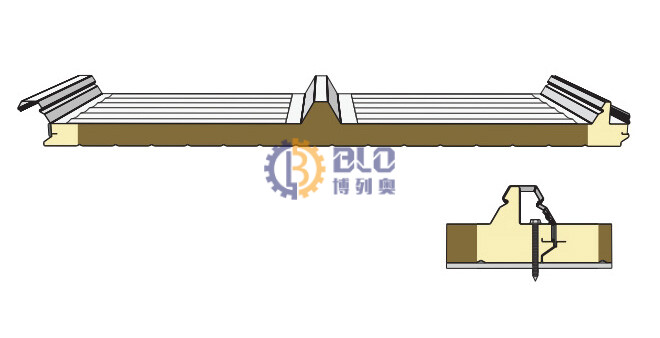

Roof PU and Rock Wool Composite Panel

Advantages: Compared with traditional thermal insulation composite panels, this roof panel greatly shortens the installation time.

The traditional overlap method is replaced by hidden overlap with multiple sets of fixing clips. This feature significantly improves the bearing capacity of the board. The special edge overlap design makes the boards tightly connected, while the drain groove design can prevent any leakage.

The professionally designed overlap structure gives this roof panel the following characteristics: stable quality, beautiful panel shape, small slope, high strength, hidden screw fixing, no external leakage holes on the roof, and easy installation.

Advantages: The self-supporting composite panel is made of an outer layer of corrugated steel plate and a polyurethane foam core material, which has excellent thermal insulation effect.

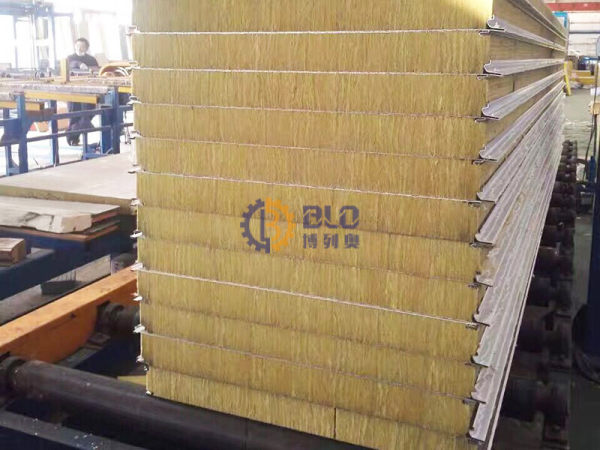

Rock wool sandwich panels can be used for projects with high requirements for fire protection. The rock wool fibers are perpendicular to the metal panel, and the high-density strip rock wool is staggered along the length of the board, ensuring that the roof panel has good bearing capacity.

The rock wool core material is a non-combustible material. According to the Italian authority Instituto Giordano S.P.A., the panel thickness is 100mm--120 minutes, the panel thickness is 80mm--60 minutes, and the panel thickness is 50mm--30 minutes.

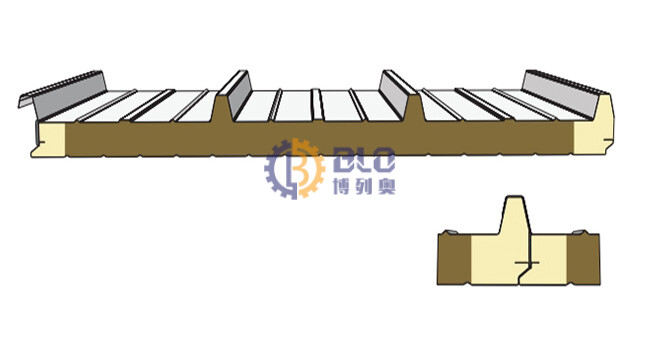

Wall PU and Rock Wool Composite Panel

Advantages: Self-supporting composite panels with hidden tongue-and-groove lap joints, beautiful appearance, easy installation, can be installed horizontally or vertically. Excellent heat insulation, fireproof and thermal insulation properties can be used in most fields.

1. The outer steel plate of the board can be made flat, embossed, small corrugated, or ribbed.

2. The effective width of the board has various styles such as 700mm, 800mm, 900mm, and 1000mm.

3. The thickness of the board can be 40mm, 50mm, 60mm, 75mm, 80mm, 100mm, 120mm, and 150mm according to the regional environment and design requirements.

4. This board type can be used as PUR/PIR polyurethane series insulation board, and can also be used as rock wool series (polyurethane end-capped, pure rock wool) fireproof board.

02

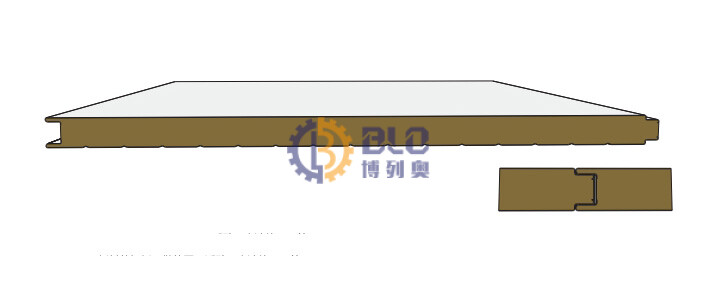

Pure Rock wool panels

Rock wool panels are high-performance sandwich panels that incorporate a rock wool or stone wool core for insulation. These panels are widely used in construction for their outstanding properties.

Fire Resistance

Rock wool panels offer the highest fire protection, classified as A1 (non-combustible). This makes them an excellent choice for buildings requiring enhanced safety measures.

Thermal and Acoustic Insulation

The stone wool core provides excellent thermal regulation and acoustic insulation, ensuring energy efficiency and noise control in various applications.

Durability and Strength

These panels are typically constructed with top and bottom layers of materials such as pre-painted galvanized iron (PPGI), zinc, or aluminum sheets, ensuring robustness and long-lasting performance.

Water Resistance

Some rock wool panels are treated to enhance water resistance, adding another layer of protection against environmental factors.

Lightweight and Easy to Install

Despite their strength and insulation properties, rock wool panels are lightweight and easy to handle, facilitating efficient installation.

These qualities make rock wool panels ideal for industrial, commercial, and residential building applications, providing safety, comfort, and durability.

1. The outer steel plate of the board can be made flat, embossed, small corrugated, or ribbed.

2. The effective width of the board has various styles such as 600mm, 700mm, 800mm, 900mm, 1000mm, 1100, and 1120mm.

3. The thickness of the board can be 50mm, 75mm, or 100mm according to the regional environment and design requirements.

4. This board type can be used as PUR/PIR polyurethane series insulation board, and can also be used as rock wool series (polyurethane end-capped, pure rock wool) fireproof board.

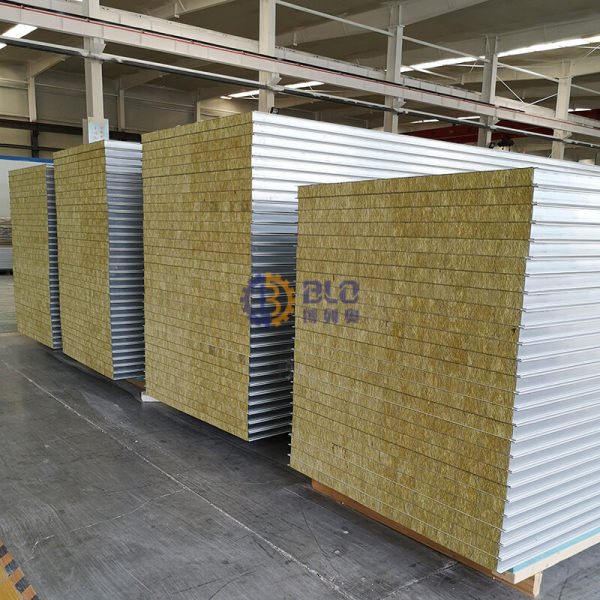

Finished products

BLO company specializes in manufacturing high-quality PU (polyurethane) rock wool composite panels and pure rock wool panels, tailored to meet diverse construction and insulation needs. Our products are known for their excellent fireproofing, thermal insulation, and durability, making them ideal for various industrial and commercial applications.

We also offer customization services, enabling clients to provide their own design drawings. Our experienced team ensures that all custom panels meet exact specifications and quality standards.

We warmly welcome clients to reach out for consultations or inquiries about our products and services. BLO company is committed to providing reliable solutions for your project needs.

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!