A Downpipe Forming and Bending Integrated Machine is an automated system that combines roll forming, bending, punching, and cutting to produce downpipes (rainwater pipes) in a continuous process. Here’s a step-by-step breakdown of how it works:

1. Material Feeding

A coil of metal sheet (galvanized steel, aluminum, etc.) is loaded onto an uncoiler.

The sheet is fed into the machine through a straightening unit to ensure flatness before forming.

2. Roll Forming (Pipe Shaping)

The flat metal strip passes through a series of forming rollers that gradually bend it into a cylindrical or rectangular downpipe profile.

Each set of rollers progressively shapes the metal until the final pipe shape is achieved.

Edges may be hemmed or seamed for a secure lock.

3. Punching (Optional)

If needed, the machine can punch holes (for screws, brackets, or drainage) using a hydraulic or servo punching system.

Some machines also notch the pipe ends for easier joining at bends.

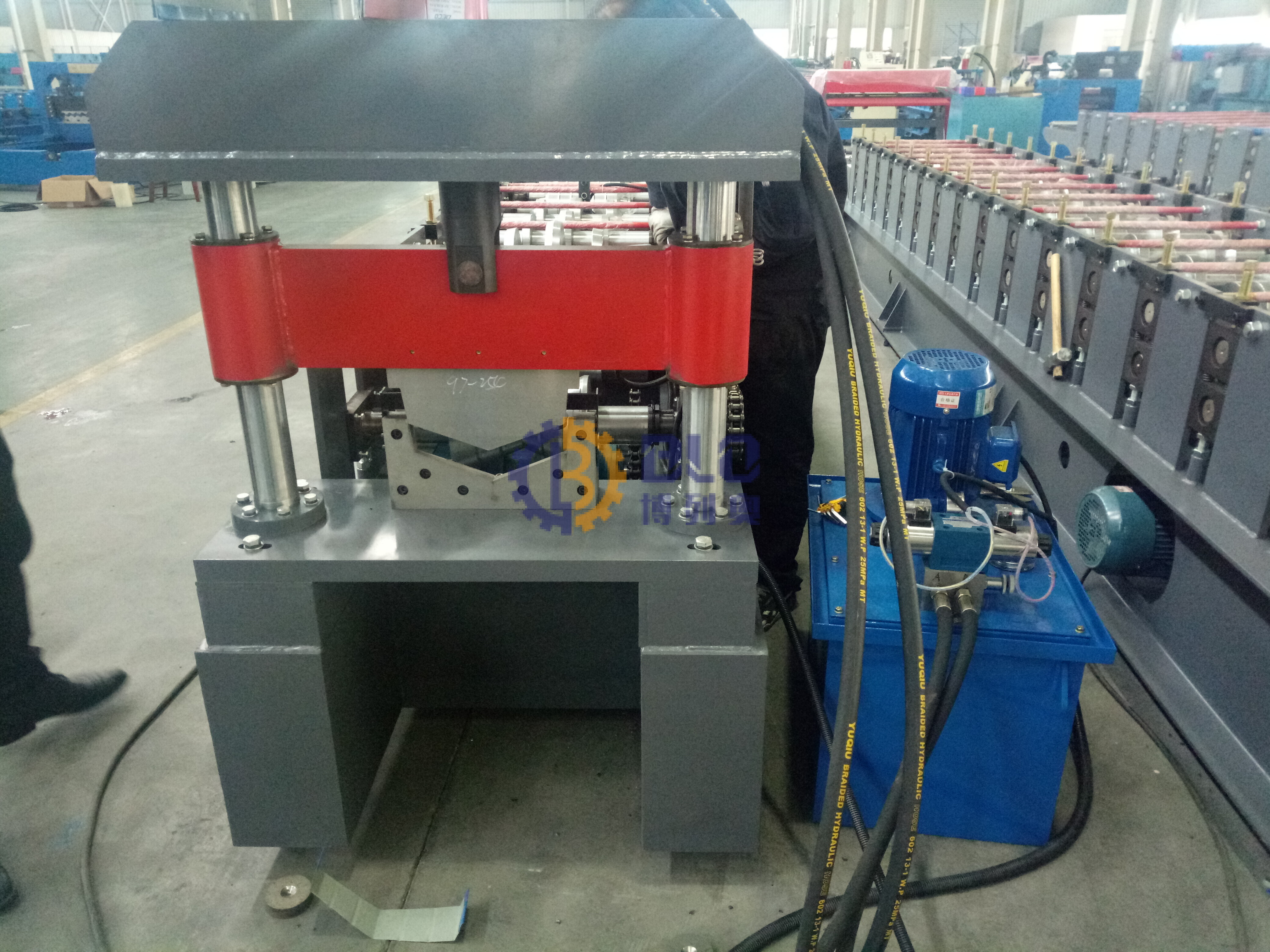

4. Bending (Elbow Formation)

The formed pipe moves to the bending station, where a CNC-controlled hydraulic or servo bender creates angles (e.g., 90°, 45° elbows).

The machine may use mandrel bending to prevent pipe deformation.

Some systems cut the pipe before bending, while others bend first and then cut.

5. Cutting to Length

A flying cut-off saw or hydraulic shear cuts the pipe to the desired length.

The cutting is synchronized with the forming speed to ensure precision.

6. Output & Stacking

Finished downpipes (straight sections or pre-bent elbows) are discharged onto a conveyor or stacking table.

Some machines include an automatic stacking system for organized output.

Advantages of an Integrated Machine:

✅ Single-step production (no need for separate bending/forming machines).

✅ Consistent quality with minimal human error.

✅ High-speed output (e.g., 10–30 meters per minute).

✅ Customizable for different pipe diameters (e.g., 3"–6") and shapes (round, rectangular).

Applications:

Roof drainage systems

Gutter manufacturing

HVAC ductwork

Custom metal piping

Latest Post

What is a ridge cap roll forming machine?2025-04-18

What is a ridge cap roll forming machine?2025-04-18 Custom Auto Stackers: Enhancing Efficiency in Material Handling2025-04-09

Custom Auto Stackers: Enhancing Efficiency in Material Handling2025-04-09 How Automatic Wire Mesh Welding Machines Boost Efficiency and Reduce Costs2025-04-07

How Automatic Wire Mesh Welding Machines Boost Efficiency and Reduce Costs2025-04-07 What Is Double Layer Roof Panel Roll Forming Machine2025-03-28

What Is Double Layer Roof Panel Roll Forming Machine2025-03-28 Downspout Roll Forming Machine in Gutter System2025-03-21

Downspout Roll Forming Machine in Gutter System2025-03-21

Ask For A Quick Quote

If you are looking for more information on our services, or how we could potentially help, we would love to hear from you!